Inkjet: Implications for Book Printing Manufacturers and Publishers

For the past few years, the publishing industry has been anticipating the shift to digital print production in book manufacturing. Publishers have eyed digital printing as a way to better manage inventories and reduce production costs. The challenge for book manufacturers has been finding digital printing technology options that are capable of achieving the quality, speed, flexibility, and affordability of offset printing. These challenges have finally met their match—Canon Solutions America and its partners offer high-speed inkjet digital printing technology that delivers enhanced makeready and the ability to turn jobs around at unparalleled speed, without sacrificing quality.

Last year, Barbara Pellow and Jim Hamilton of InfoTrends discussed innovations in inkjet technology during a one-hour webinar entitled Inkjet: The Implications for Book Printing Manufacturers and Publishers. During this webinar, Barb and Jim tackled topics including emerging technologies for book production, the impact of high-speed inkjet on the publishing market, and the traditional offset versus high-speed inkjet digital business model and its financial implications. Key highlights from the webinar are outlined below.

Shifting Distribution Models

The digital era is changing the book publishing market on many fronts. For one thing, inkjet printing is disrupting the traditional warehousing and distribution model. Historically, publishers looked to achieve low per-unit manufacturing costs by printing long runs. This resulted in the “Publisher’s Dilemma”—what was the best way to accurately forecast book demand to meet sales requirements while minimizing the costs of overruns? With today’s production digital printing methods, publishers can meet distribution channel requirements more effectively with shorter “just-in-time” runs. This method of printing books as needed supports the publisher’s need to warehouse books in digital formats while also solving warehousing and distribution issues, effectively eliminating the Publisher’s Dilemma. To manage this process efficiently, book manufacturers need workflow software.

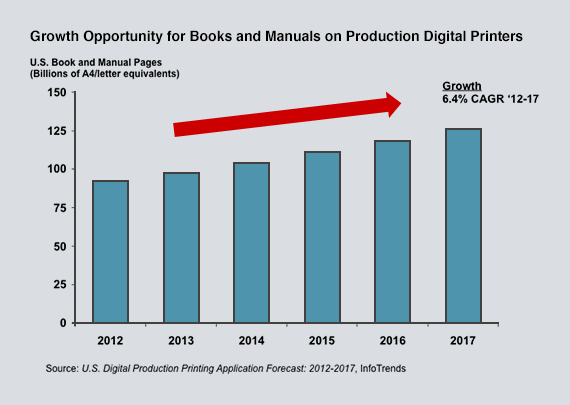

So what is inkjet’s role in all of this? The answer lies in page volume trends. Books and manuals offer healthy growth opportunities for the production digital printing market. InfoTrends forecasts that books and manuals will increase at a compound annual growth rate (CAGR) of 6.4% through 2017. It is important to note that a fair amount of this growth will not occur in the book market, but book printers and publishers are realizing that production digital print provides a more effective means of manufacturing their printed content. As a result, volume that would have been printed on offset presses is shifting to cutsheet and continuous feed devices at a rapid rate.

Technology and Customer Demands are Driving Inkjet Investments

Customer needs, combined with the availability of fast, high-resolution inkjet print engines, have caused continuous feed color inkjet system placements to increase. While much of this investment activity has occurred in direct mail and transaction environments, book printers have also made significant investments. In addition, some monochrome-only inkjet systems have been placed in book production environments.

Overcoming Barriers to Transform Operations

The major barriers to implementing digital printers are generally cost and productivity. With inkjet, high levels of speed and productivity are required for book printers producing millions of impressions per month—and many book printers are producing at those volumes. It follows that if other print requirements (for example, color, format, substrate, and workflow automation) are met, there is an opportunity for process improvement and ultimately business transformation.

High-Speed Inkjet is Meeting Book Publishers’ Needs

Because of its greater flexibility, high-speed inkjet printing enables book publishers to meet their clients’ needs by filling channels appropriately and economically while also enabling them to gain revenue from backlists and on-demand orders. High-speed inkjet offers three key advantages for book publishers:

- Electronic collation: The book can be printed in page order, or any order that suits the production process. This is very important because it allows the in-line creation of book blocks that are ready for binding.

- Just-in-time manufacturing: This makes it possible to fulfill the publisher’s supply chain as needed, which helps prevent the Publisher’s Dilemma.

- Workflow automation: One operator can handle a production color inkjet system and, depending on the finishing configuration, is able to handle tasks that are typically the responsibility of multiple operators in an offset environment (for example, platemaking, press operation, and finishing). Digital printing also removes platemaking from the printing process, which has ecological benefits (as in, no platemaking chemistry).

The Bottom Line

The good news is that digital print is creating new opportunities. High-speed inkjet digital printing is enabling publishers to meet the market’s need for short runs. In addition to addressing title proliferation, it provides higher page value through color, customization, and automated finishing. It also offers new business models (for example, mass customization, personalization, self-publishing) and increases supply chain opportunities (for example, print on-demand, just-in-time manufacturing, test marketing, back list extension).