On-Demand Book Printing Gets an Upgrade with Canon Solutions America’s New Book Smart Suite

Nearly three decades ago, sometime in the early 1990s, a new term emerged: on-demand book printing. The promises of this technology seemed extravagant at the time—could physical inventories of books be eliminated and replaced by a system in which books were not printed until ordered and paid for?

The technology was met with a lot of skepticism, and for good reason. In addition to limitations with the printing technologies available at the time, there were concerns about the ability of inventory and order management, workflow, front ends, and finishing systems to meet the production needs of on-demand, book-of-one virtual inventories.

It is easy to see how the landscape has changed over the past 30-plus years. On-demand printing workflows are now broadly accepted by publishers around the world for many types of publications?—?not just books! Publishers have made extensive efforts to archive and control their electronic assets. In addition, this area has seen more rapid progress due to the introduction of high-speed, roll-fed production color inkjet printing systems capable of producing high-quality work on an ever-increasing range of substrates. Inventory and order management, workflow, front ends, and finishing systems also evolved, making it possible to achieve what was dreamed of when the term on-demand book printing first came into common use.

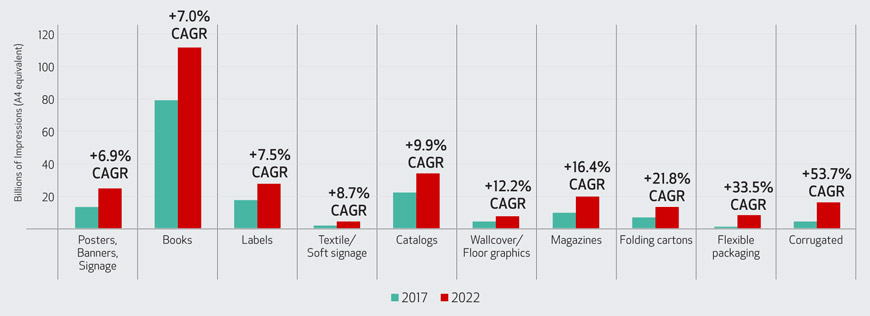

10 Fastest Growing Applications (Growth Rate)

Source: U.S. Digital Production Printing Application Forecast: 2017–2022, Keypoint Intelligence—InfoTrends.

What’s the Opportunity?

According to Keypoint Intelligence—InfoTrends’ U.S. Digital Production Printing Application Forecast, books are currently the largest application for digital printing. With impressions expected to increase from 78 billion in 2017 to over 110 billion in 2022, books are leading the digital production printing transition. High-speed inkjet technology updates, increased market education, and complementary workflow integration largely account for this growth.

Books are currently the largest application for digital printing [and] books are leading the digital production printing transition.

NPD BookScan reports that book sales continue to see modest growth (+1.3% between 2017 and 2018). In the past few years, there has been a particularly strong uptick in hardcover book sales.

On-Demand Technology Creates Demand!

Early print-on-demand book production sites often used toner-based, cutsheet digital printing technologies for the interior book block as well as the cover, although some used roll-fed toner devices to create the book blocks and paired them to cutsheet production technologies for covers. These digital production sites enabled publishers to print books in small quantities for purposes such as proof copies, niche titles, university course packs, and back catalog production. The on-demand model created a range of new opportunities for self-published writers, trainers, educators, consultants, and other content developers. With the help of online providers, these authors could upload and sell their work without investing in printed inventory. This model also piqued the interest of publishers, who realized they could personalize and repurpose content in a variety of ways?—?electronically and in print.

The role of on-demand book printing greatly expanded over the past decade with the introduction of high-speed monochrome and color inkjet web-fed printing systems. While toner-based color and monochrome roll-fed printing systems are still sometimes used for on-demand book printing, inkjet systems have had a revolutionary effect that is truly extending the reach of the on-demand book printing market. The speed capabilities and productivity of inkjet systems have made it possible to print larger quantities at competitive costs while also embracing the values of digital printing (e.g., quick turnaround, personalization, just-in-time production, and on-demand printing).

Let’s Talk about Workflow!

Book manufacturers need a fully automated book production workflow. Otherwise, they will have production silos and inefficient communication gaps between systems. From onboarding through job batching, imposition, tracking, and printing, book manufacturers can reap the benefits of a workflow system that can better manage inventories, reduce production costs, and increase speed to market. This is where Canon Solution America’s Book Smart Suite comes into play. The Book Smart Suite enables book manufacturers and publishers to maintain lower inventory levels, quickly bring products to the market, and ensure the availability of backlist titles. For printers that have experienced an increase in print-on-demand or one-off book requests, the Book Smart Suite provides an answer. This automated, end-to-end solution is designed to help you add valuable service offerings and increased flexibility without interrupting existing workflows. Scalable options mean that the suite can be tailored to your needs today while also remaining flexible enough to grow with you tomorrow.

VIEW THE INFOGRAPHIC