How Inkjet Technology is Transforming Book Printing

If you walk into any bookstore, at least some of the books you find will have been printed on a production inkjet press. Many materials you find in training classes, as well as school textbooks and college course packets, are being produced on highly capable inkjet presses to meet the changing needs of book publishers of all sizes and segments. According to Keypoint Intelligence—InfoTrends’ 2018 Applications in Digital Print Survey, books represent a strong and growing component of the digitally printed product mix, as publishers and their printers seek ways to create just-in-time manufacturing processes that reduce warehousing costs while offering more options for customization.

Book production is often identified as one of the fastest-growing digitally printed applications in InfoTrends’ research as more and more printers augment book production with inkjet presses. Some are even eliminating their older technologies in favor of inkjet. This rise in digital production can be attributed to the following:

- A growing number of inkjet devices available in the market

- A wider range of possible configurations

- Ongoing inkjet innovations that enable higher speeds, wider color gamuts for full-color work, and access to a wider range of appropriate substrates for book printing

There is now an inkjet device for every type of book printing, and there are also many options for building automated book workflows with a limited number of physical touchpoints. Coupled with workflow innovations and finishing best practices, inkjet technology is paving the way for a growing range of product offerings that enable expanded digital printing capacity.

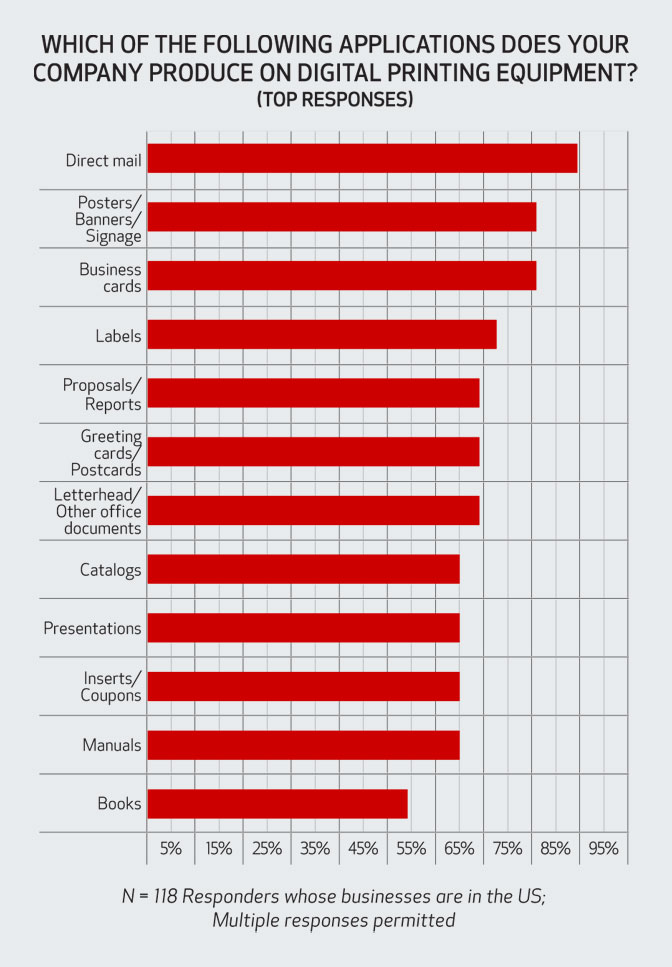

Digital Printing Applications

Source: Applications in Digital Print Survey, Keypoint Intelligence—InfoTrends.

What’s Your Product Mix?

Let’s start with the product mix. No matter which formats you print and what type of finishing you need, there is an appropriate inkjet solution. Inkjet printing is typically used for the book block, while covers are printed using toner or analog printing solutions. With newer inkjet technology like the Océ ProStream™ series, you can also print covers on an inkjet press with a heavier paper weight and UV coated for added durability. In today’s book environment, it is possible to print the entire book on inkjet. During the book assembly process, all book parts are brought together to create the final product.

Although your current product mix may be one or many formats, there is typically a common attribute for books—the content is usually static. An upgrade to inkjet opens the door to selling book products that enable content variation within the print run. This creates the opportunity to introduce new products, extend existing offerings, and even offer alternative pricing based on the ability to customize and personalize.

Consider the opportunity if a book product enables the author or publisher to personalize every copy. For example, inkjet technology is perfect for personalizing children’s books by including the child’s name throughout the text. Other areas of the book could also be customized based on the child’s age, gender, or location to create a high-value, high-margin product. Family histories can achieve higher value by printing dedicated versions for each family member. Course packets could be customized for each individual student, enabling educators to introduce new material only when the specific student is ready for it. Products like these and more have already been created using inkjet printing technology.

The power of inkjet technology comes in the form of productivity matched with quality. Many companies report that the acquisition of a new inkjet device has enabled them to eliminate some of their analog and digital toner presses from their inventory (along with the maintenance that goes with them). Meanwhile, these devices also make it possible to add color at a reasonable cost. They lower overall production costs while producing more books within the same or smaller footprint than other technology options. One of the key decision points for shifting to inkjet technology for book printing should be the number of new products and higher value products you can offer to your customers.

What Changes in Your Production?

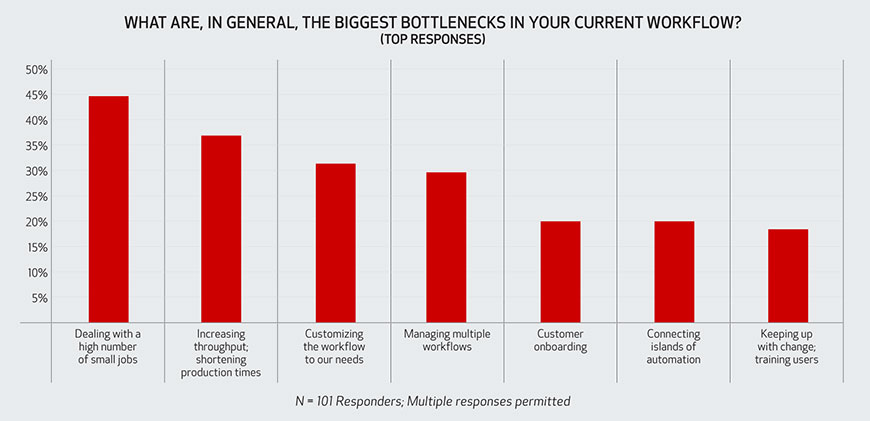

Although inkjet is an enabling technology that can bring higher capacity and expanded features to book printing, effort is required to make the most of it. Take the time to assess your current end-to-end workflows and identify how you will deal with the increased capacity and functionality. Book printers tell us the addition of inkjet technology has eliminated many common workflow bottlenecks, enabling them to handle more jobs and achieve shorter run lengths and faster production times. Success can multiply by automating as many touchpoints as possible.

If you’re already running an automated workflow today, congratulations—you’re on the right track! Even so, take the time to review the automation points to determine if they will handle the larger number of jobs your inkjet press enables. If you’re printing color, review your color management protocols to ensure your files are prepared for the power of the inkjet color gamut. It’s also important to review your finishing processes. Inline finishing can provide great efficiency so long as it keeps up with the press. Finally, review your shipping and delivery processes to verify that they can keep up with the changes in output cadence as you add new products.

Enabling the Power of Inkjet for Book Printing

Your decision to implement inkjet technology for books can open doors to new workflow options and the production of new, higher value publishing products. The speed of inkjet printing can bring you additional capacity for mass customization and even personalization of published works while providing a cost-effective path for short-run work. Once you’ve considered all the options, they will likely lead you to book printing with inkjet technology!

WATCH THE VIDEO